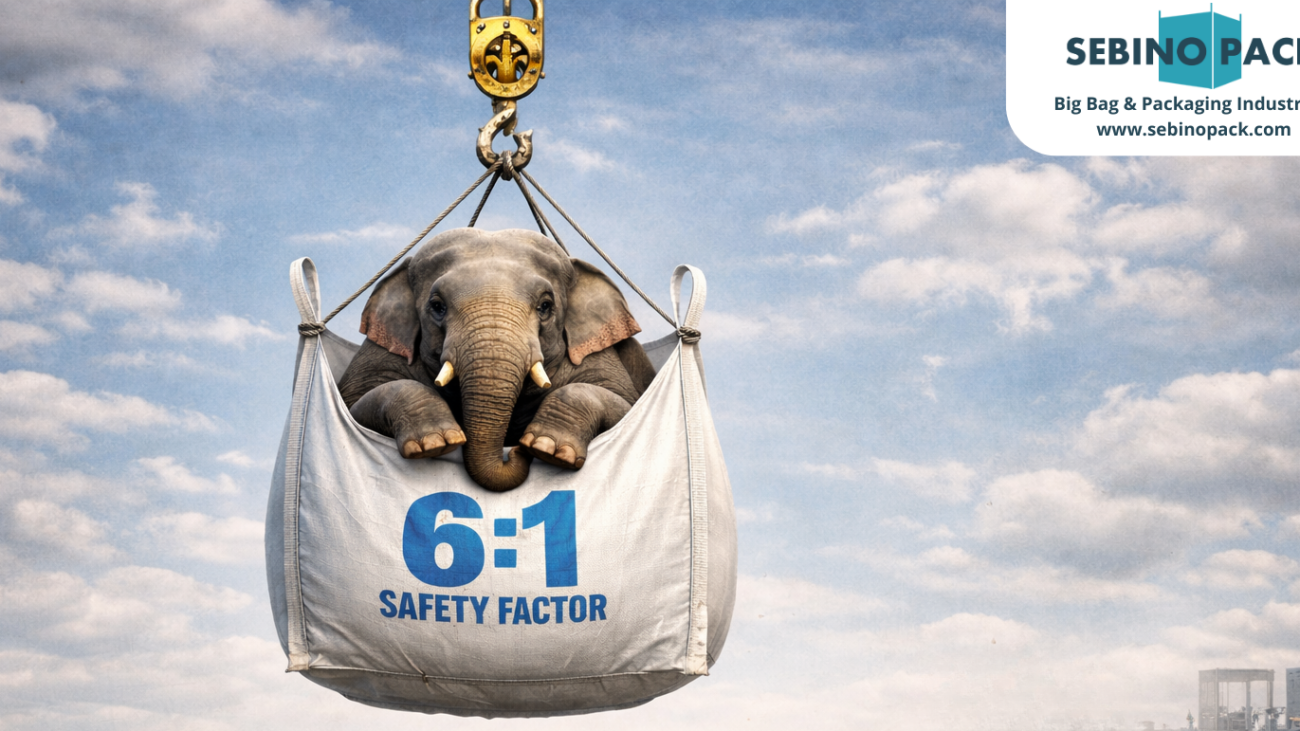

In the world of circular logistics, a multi-trip Big Bag (6:1 certified) travels, supports immense loads, is emptied and refilled. But like any veteran, it collects “scars” over time.

For a safety manager, being able to distinguish between a surface scratch and structural damage to the fabric is critical. An error in judgment can mean a sudden failure.

Woven polypropylene is like a skin: as long as the fibers are cohesive, the structure is indestructible. When the weave frays, the load-bearing capacity collapses exponentially.

Big Bag often rubs against wooden pallets or container walls during handling. Therefore, it is worth checking for the presence of a slight fuzz on the surface of the fabric. If it is only“pilling” (small raised fibers) and the underlying weave is still firm and rigid, the bag is sound. This is a sign of aesthetic wear and tear that does not compromise the Safety Factor.

Another thing to check are the buttonholes: are there fraying at the base of the seam or sharp cuts at the edge of the strap? If you notice injuries, the bag can no longer guarantee stability. Never attempt to repair a buttonhole with handcrafted stitching.

Polypropylene is sensitive to prolonged sunlight, which alters its molecular structure, making it brittle: if the fabric appears faded, dry to the touch, or produces a white powder, there is little to be done. These signs indicate that the Big Bag has lost its elasticity.

If you notice cuts greater than 2-3 cm, or tears near a load-bearing seam the structural integrity is gone. Pressure from the internal material will widen the wound in seconds during the next lifting.

Before each reuse of a 6:1 Big Bag, also check these 4 points:

- Readable label: if the 6:1 factor label is torn or illegible, the bag should be downgraded or discarded (its history cannot be traced)

- Internal cleaning: residues from previous loads can contaminate or create chemical reactions that weaken polypropylene

- Bottom integrity: check the drain valve; it is the point that suffers the most stress during emptying

- No knots: loops should never be knotted to shorten them; knots reduce the strength of the strap by 50%

A SebinoPack multi-trip Big Bag is designed to last a long time, but its safety also depends on your observation skills. Treating your containers with respect and knowing how to read their signs of wear and tear is the best way to protect your goods and, more importantly, your employees.